Olamic Cutlery Wayfarer 247

Nick Clayton

The Wayfarer 247 is a variation of the original Michael Vagnino designed Wayfarer model. The Wayfarer is Olamic's signature folding knife design with their motto "Never the Same" ringing true as there are many MANY different examples of it. The Wayfarer is a custom knife fully furnished in-house while the 247 is not.

The 247 is a new project for Olamic as their first "mid-tech" (I use quotes here because that phrase means something different to everyone). The majority of the knife is machined in Italy and the final finishing done by Olamic. Some might argue that this is more of a production knife but this has largely become an argument of semantics and I will avoid that for this review. Instead we'll focus on the knife itself and what is gets right and wrong.

I've handled two of the three 247 models that will be available, the darkwash and the plain Ti. There is also a fancier version that is similar to the plain model but with a mokuti pocket clip and inlay, with the possibility of more options down the road. The darkwash type finish is not one I am very fond of, I much prefer the plain ti. I will focus this review on the plain one as the darkwashed one was also a prototype and not 100% indicative of the production run.

So enough backstory, lets get moving.

The overall shape of the Wayfarer is very unique. With the handle growing towards the rear, it has, what some may call, a booty. The larger portion of the handle near the rear might look strange at first glance but actually lends itself well to a proper grip. The sloping of the handle seats nicely in your hand with plenty of room for all four digits.

The blade shape is a combination of a drop point and a spear point. There is a downward slope towards the tip of the knife and there is a nice swedge that gives a spearpoint profile. The blade is well finished with noticeable grind lines and a polished treatment. It's both handsome and utilitarian. The blade steel is Elmax which, despite past claims, is a great steel.

The hole in the blade is actually useful as an opening method if done slow and deliberate. I can't use it quickly with my thump or middle finger, though. The main way to open the knife is, of course, the flipper tab.

Keeping in mind that the knife I have is only a week or so old, the action on the knife is smooth but not free-falling. This is not necessarily a knock against the knife. There are lots of collectors who dislike a completely free-falling blade. Opening is extremely fast due to proper flipper geometry and just-right detent strength. There is a neat area above the flipper on the frame that is a perfect seat for your finger to sit. This makes light-switching a breeze to get right despite the lack of any meaningful traction on the flipper tab.

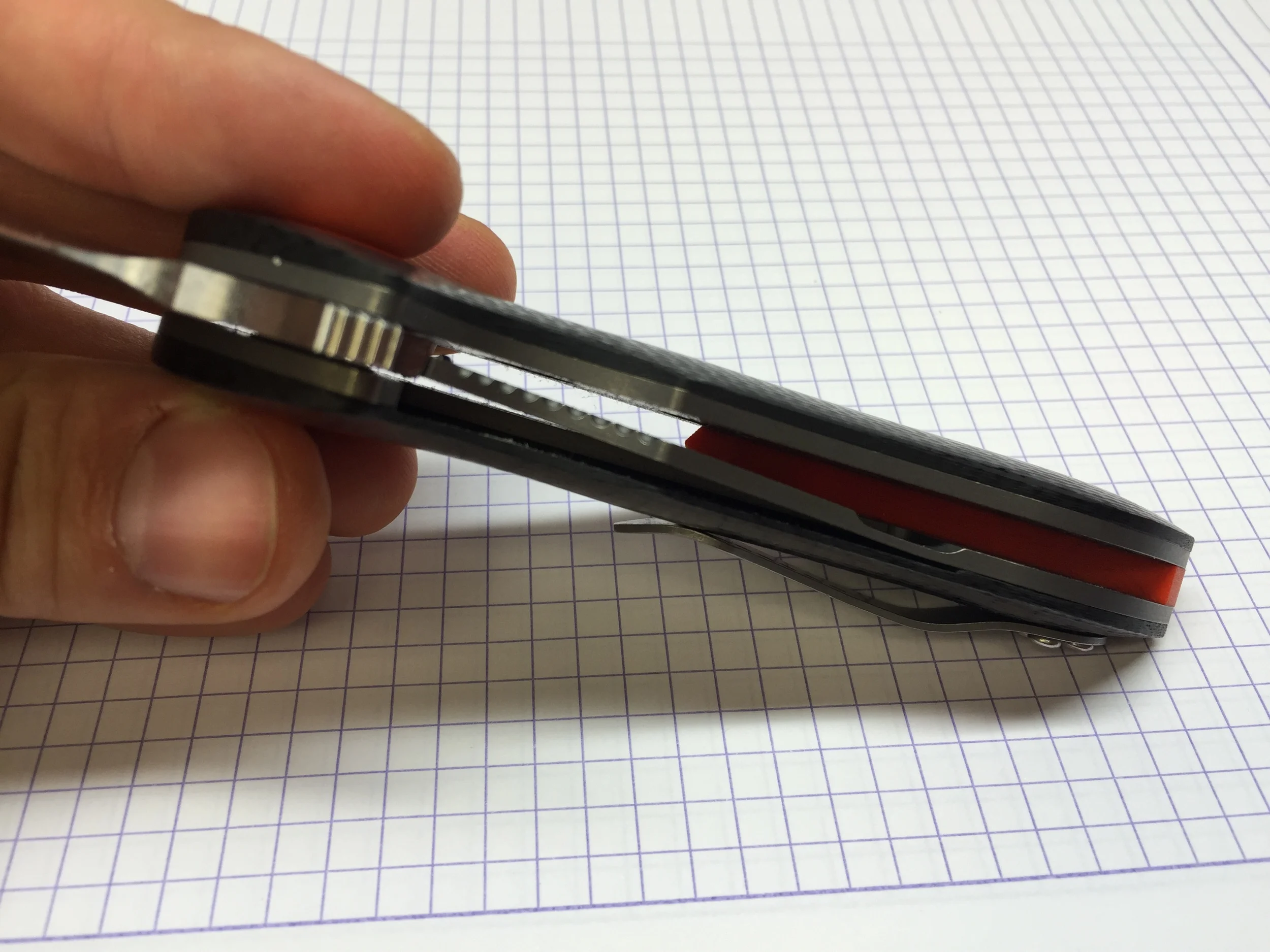

The 247 is a frame lock design with a stainless lock insert/over-travel stop secured by two titanium screws. This has become the standard set of improvements to the Reeve Integral Lock. The over-travel stop prevents damage to the lock while the insert provides a more solid surface which to lock up. There is a cutout ramp to allow the detent ball to ride up so there is no hard shelf to overcome when closing. This is not something that is present on all designs and it's welcomed.

The pivot required custom hardware and the tool is included. I am not a fan of this practice. I understand the design aesthetic etc. but I would rather have a more standardized hardware slot. Sure it looks good but lose that little tool and you're in for a wait to just adjust your knife.

The pocket clip is interesting. It's a flat titanium clip attached by 3 standoffs that are threaded into the frame then tapped to accept the screws that hold the clip and it uses a large ceramic ball to secure it in pocket. This is all in place of any bending and adds a lot of parts and detail to an otherwise mundane part of the knife. It works well and it's nice to see the attention.

Overall the knife is very well done. There is a lot of attention paid to smaller details that really show that Olamic cares about knife design. Not only that but the knife is perfect. It's perfectly centered, the grinds are even, the finishing is even, the backspacer ( a solid free-floating unit) is centered and matches the frame, etc.. I really can't find any flaws in the finish. Combine the expert build with a great attention to details and I predict the 247 will make a lot of knife guys happy.